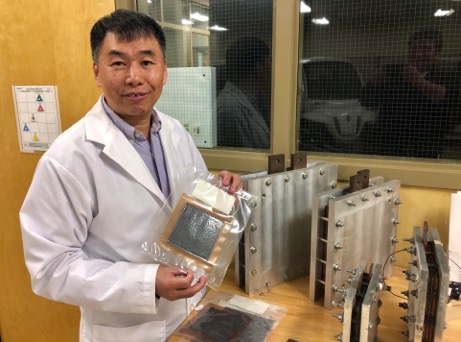

Waterloo’s Green Energy Labs unveils a new form of electric cells that remain robust without trading away an inexpensive manufacturing cost. The project is headed by Xianguo Li, a UW professor of mechanical and mechatronic engineering.

The matter of developing zero emissions technology usually becomes a matter of cost versus effectiveness. Different potential solutions have already come up, one of which being hybrid cars, which still use gas engines as a backup for the batteries that usually provide power and usually become expensive due to their electric power sources.

On the other end of the spectrum, there are fully electric cars which often need to trade even more cost-effectiveness to remain a reliable means of transportation. In both cases, developing a fuel cell that can power a vehicle becomes very expensive.

Li’s project can solve these issues with hydrogen cells. A hydrogen cell is common form of energy cell that uses the conversion of hydrogen and oxygen into water as a means to produce power, not dissimilar to the way an ordinary battery uses the chemical reactions between two different materials produce power. Because of the nature of the reaction, hydrogen cells can be easily recharged once depleted making them an ideal candidate for green energy.

But where most hydrogen cells produce a fluctuating amount of electricity, the ones developed by Green Energy Labs produce a constant amount of electricity. This drastically increases the durability of the cells and, therefore, means that production becomes cheaper.

Furthermore, the cells have been tested to last ten times longer than current technology, a feet that makes them desirable to integrate into the market.

In a University of Waterloo press release, Li stated that in testing, the cells had been able to meet both economic and durability standards. By introducing these into hybrid and electric cars, the cost of these vehicles could drastically decrease, making these technologies more available.

In the same press release, Li noted that, “With our design approach, the cost could be comparable or even cheaper than gasoline engines.”

He also described this as a possible first step in the elimination of internal combustion engines.

Integration of these cells into the market could have a large impact on the auto industry. Until now, the only way to produce a zero emission vehicle was by allocating large amounts of resources.

This type of development could change industry standards and make electric and hybrid vehicles more accessible to the general public.